The Favorable Aspects of Using Rapid Prototyping in Manufacturing

For many years, urethane casting and rapid prototyping contributed a lot of benefits to the manufacturing industry. Until now, a lot of manufacturing companies around the globe are still using rapid prototyping and the methods used for this has improved a lot in the past few years.

Rapid prototyping is one of the methods used by manufacturers to create objects that will be analyzed and observed before they produce the final product of the company. Well, manufacturers will not be using this method if they do not obtain a lot of benefits from it. If you are a manufacturer, below are some of the many benefits that you can obtain from rapid prototype.

Designing Products

Basically, you cannot simply say that the design of a product is already good just by checking out the drawing or illustration of a designer. The designs of the product must be made into physical form first and turned into reality so you can easily decide if it is good or not. Prototyping is used to make the designs a reality and help the manufacturers improve the looks of the product by creating them. The creation of prototypes will be continuous until the design that they wanted will be made.

Track the Design Process Effectively

Through the help of rapid prototyping, like what is mentioned earlier, the designers can track down all the changes and improvements on the design. They can note all the changes made and create improvements easily for the next prototype without any problems.

Prevents Problems on Manufacturing

Prototyping can prevent any kind of defects on the products created by the company so it is a good option. These defects can be prevented because through the help of prototyping, they can easily see problems on the product even before it is released to the public. It makes it easier for them to pinpoint the problem and provide solution to it and prevent manufacturing products with problems and defects.

Save Money

A lot of experts already provided information that prototyping can help companies save a lot of money from products with defects. As you can see, there are a lot of websites that can also give you a couple of information about the other benefits offered by rapid prototyping.

Always keep in mind that if you want to improve the products that you are selling on the market, you have to make use of rapid prototyping and consider all the benefits that it will offer you.

Kinds of Rapid Prototyping: Can they help your Company?

The companies on the manufacturing industry are probably aware of the different importance of rapid prototyping in the creation of different plastic parts. Prototyping is considered as one of the most important thing when it comes to the research and development of a specific product and it plays a very important role.

Basically, if a product will be mass produced, rapid prototype will be a great help since a product that is already created cannot be fixed anymore and the problems and damages will be irreversible. If you will look closely, if a product with a defect is mass produced, the company will surely waste a lot of time, effort and resources on the manufacturing. If they made 5,000 products with defects, they have to do another set again and manufacture a new set without any defects. This is a good reason why most of the manufacturers around the globe are considering prototypes before they mass produce a specific product.

If rapid injection molding will be used before creating a finish product, they can easily know if there are any defects or problems on the product. Well, creating a lot of prototypes will not be a big deal especially if you really wanted to remove all the possible problems on the product before you mass produce them and sold to the public. You will surely save a lot of time, money and effort because you no longer need to worry about the defects on the products. If you want to know the advantages of using rapid prototype, there are websites that can help you.

There are different types of rapid prototyping depending on the needs of the manufacturers.

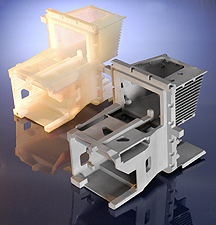

Stereolithography

This is a type of prototyping where experts make use of UV rays to solidify liquid acrylic polymer layer by layer until the part is completed. This kind of prototyping is made through the help of a machine known as VAT. It is very popular because of its accuracy and it is faster than all the other types of rapid prototype so many people prefer this.

Fused Deposition Modeling

This is a type of rapid prototyping where they make use of CAD drawings and convert them into physical parts to create a prototype. The parts will be created almost immediately since the parts are created based on the drawing.

Selective Laser Sintering

This is one of the most complicated processes in prototyping because it is a heating process where melting is prevented to produce a coherent mass. They are also using a CAD program guided laser to fuse the powdered material and make the prototype.